Industrial robotics in the Visegrad Group

18.06.2024

In recent years, the dynamics of robotization in Central European industry has significantly accelerated. The Visegrad Group – which brings together Poland, the Czech Republic, Slovakia and Hungary – is an excellent example of a region that invests heavily in the automation of production. Poland, although it lags slightly behind the Czech Republic and Slovakia in terms of robot density, is the only country in the Visegrad Group where the number of installed robots has increased on average, steadily over three-year periods since 2004.

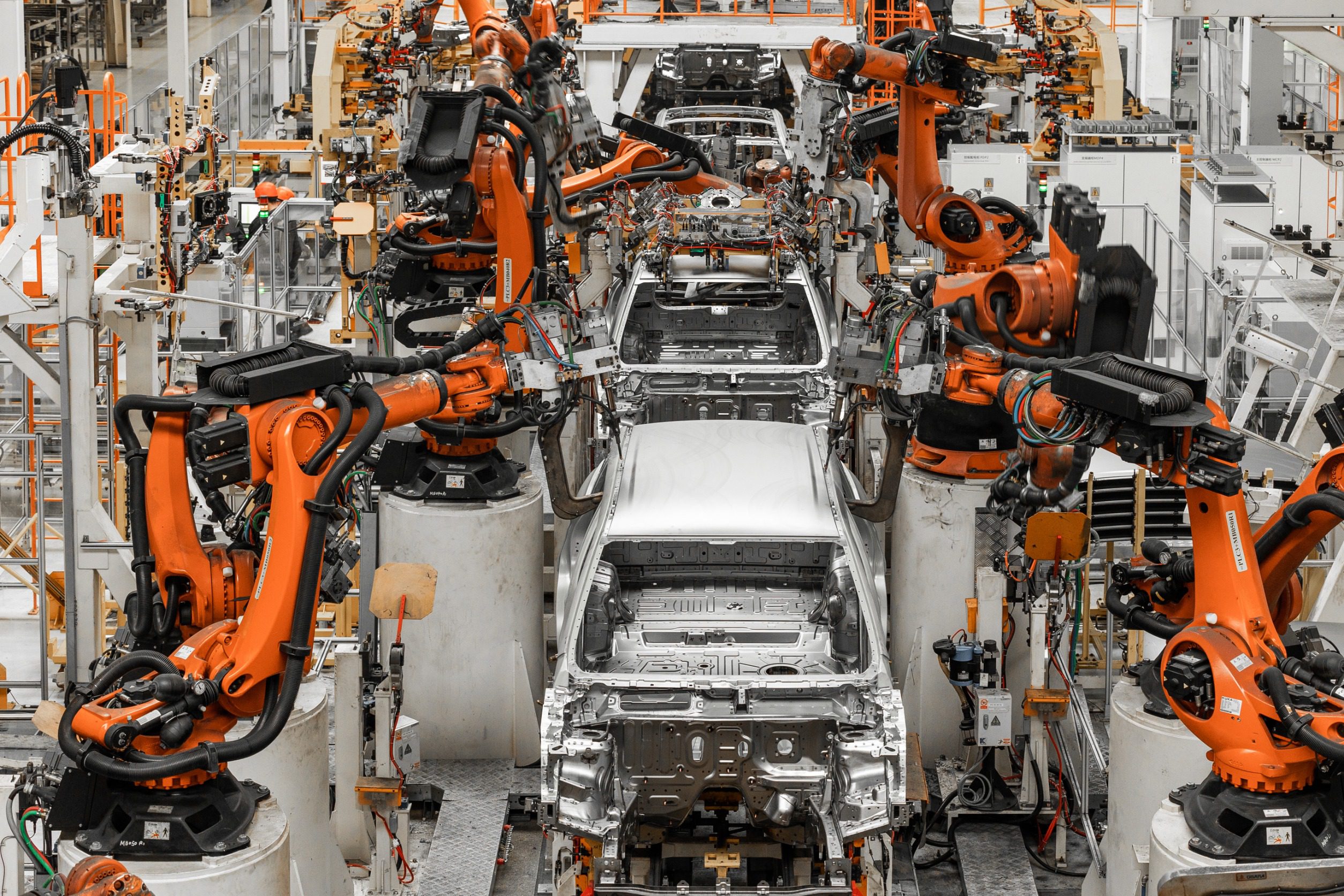

According to the data of the International Federation of Robotics, the automotive industry is the most robotic sector in each of the Visegrad Group countries. Automation in this sector is crucial due to its requirements for precision and production efficiency. In 2022, the number of robots in the manufacturing industry ranged from 9,000 in Slovakia to 225,000 in the Czech Republic, showing differences in the scale and intensity of adaptation of robotic technologies in individual countries. Poland, with 17,800 robots, is more or less in the middle, but the number of robots in the Polish automotive sector – despite accounting for 32 per cent of all robots – is smaller compared to Slovakia, where the number exceeds 70 per cent.

Robotization in Poland – overview and perspectives

According to the PIE Economic Weekly, Poland is the only country in the Visegrad Group that has recorded a systematic increase in the number of installed robots since 2004. Since 2019, an average of 2103 robots have been installed per year, which indicates a significant increase in interest in robotization. For comparison, in the years 2004-2006, an average of 190 robots were installed annually in Poland.

The growth rate in the number of industrial robots is also a reflection of global trends, where robots are increasingly used not only for production tasks, but also for collaborative (cobots) and mobile applications. New technologies such as artificial intelligence and machine learning are increasingly being implemented in robots, enabling more intuitive programming and more efficient operation of machines.

Challenges and the future of robotization in the Visegrad Group

Although the number of robots in the V4 countries lies in the European average, there is still a lack of own robotic technologies. According to PIE analysts, the increase in the number of robots should be supported by innovation and the production of their own robotic systems. Poland, as well as other Visegrad Group countries, should strive to increase their innovation capacity in this area so as not to remain dependent on foreign technology suppliers.

Sources:

- The Polish Economic Institute – Tygodnik Gospodarczy 23/2024,

- International Federation of Robotics – World Robotics 2023 – Industrial Robots

- Everything

- News (3)

- Events (5)

- Get Support (82)

-

Article

ArticleInvestors want to be in Poland

Also with a very professional staff, which guarantees high quality of work

Article

ArticleA renaissance in the EU’s tourism sector

According to data published on Eurostat’s website, European tourism recorded serious losses in 2020….

Wordfall Dominik Lisiakiewicz

Show more Show lessOur company has been developing the electronically controlled interactive event machines for more than 8 years now. Our flagship product is a water printer. It is an interactive device that prints images using falling water drops. We are constantly developing our digital water wall by adding new ways to interact with our water curtain. One of the most popular options is water swing. Our product is flexible and we can make a circular water curtain.

-

Event

EventFastener Poland

Between October the 18 and 19 in Targi Kraków, Fastener Poland the International Fasteners and Fixin…

Event

EventTAROPAK 2023

Between September the 27 and 29, in MPT Poznań, TAROPAK an International Trade Fair of Packaging Tec…

-

Institution

InstitutionKatowice City Hall – Investors Assistance Department

The Investors Assistance Department of Katowice City Hall is a unit which supports investors and ent…

Institution

InstitutionPolish Union of Designers and Engineers – ZOPI

ZOPI actively supports entities focusing their activities on design, engineering and related service…

The Export Promotion Portal uses cookies to make it easier for users to use the website and for statistical purposes. If you do not block these files, you agree to their use and saving in the memory of your computer or other device. Remember that you can change your browser settings to block the storage of cookies. More information can be found in Privacy Policy and Terms and conditions.